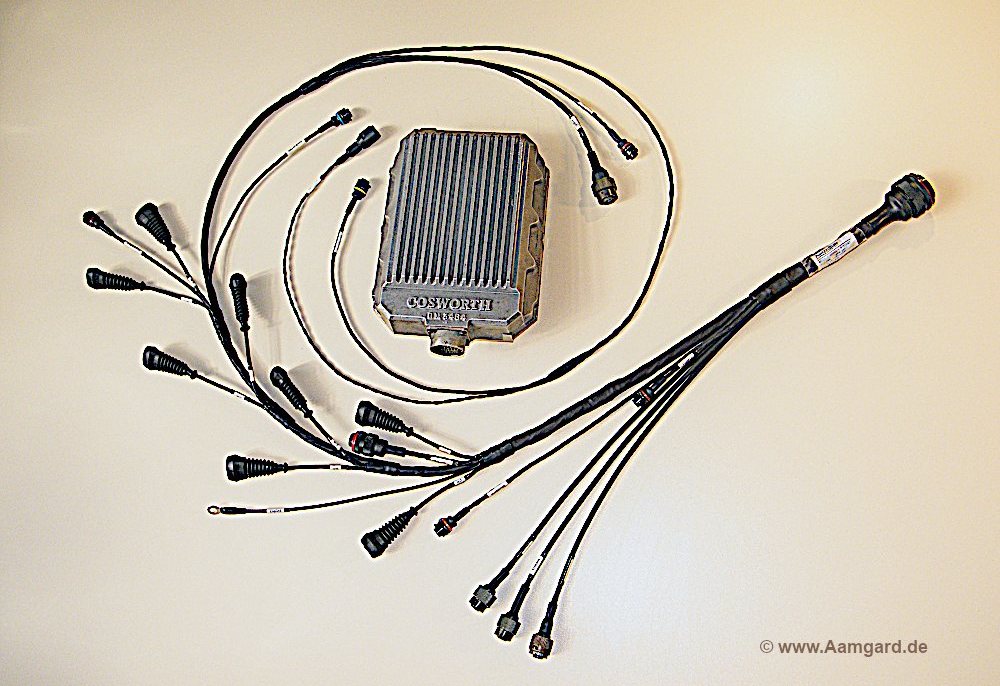

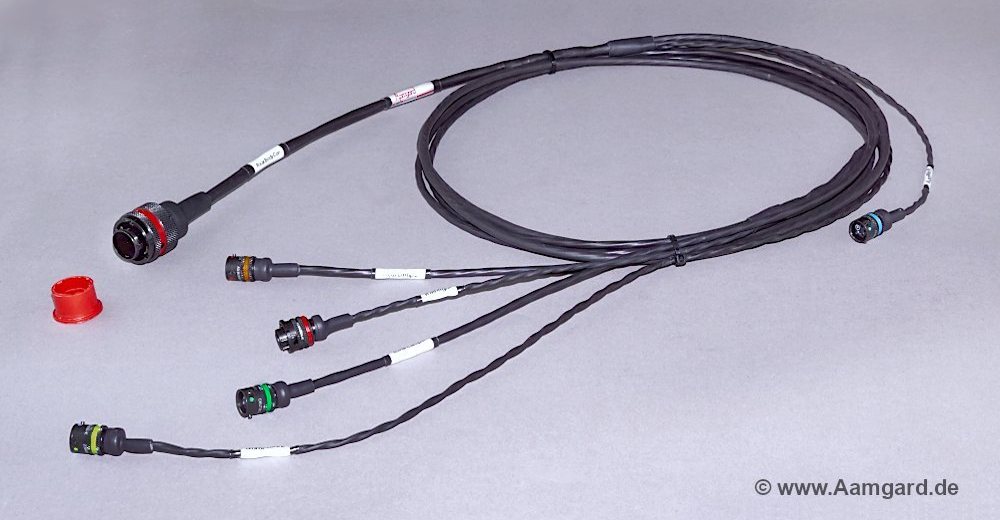

Whether engine loom or chassis electrics, if motorbike or racecar, oldtimer, youngtimer, sport boat or construction machinery: Before building of bespoken electric harnesses it needs professional system planing and overmeasure. Both is done as much as possible at the customer's location.

Others than many loom manufacturers we process two different wiring material classes: One is based on automotive flex wires (FLRY / DIN-ISO 6722) with specified final loom operation temperature of 105°C. The second system uses MIL / aerospace grade teflon wires (PTFE-5Y / DIN 57881) and is capable to deal with temperatures of min. 150°C. For special applications we can offer high temperature materials capable up to 250°C.

But most important for reliable function and durability of an electric harness is not to use absolute high-end and most expensive materials, but to choose suitable wires, heat shrinks and components and to process these with high quality craftmanship. For this craftmanship at Aamgard Engineering meanwhile stand more than fifteen years of experience in electronics and motorsport engineering. Even some of our oldest racecar wiring looms are still in duty, despite high temperature, vibration and power loads.

Continuous enhancing of personal skills and technical working methods today enables us to meet customer requirements from club sport to Formula 1. Prior to delivery each single loom is entirely tested and documented. For motorsport customers, installation and in-car startup are the usual final steps of a wiring project. Even if we spend quite higher efforts for your projects than some other loom manufacturers tend to do - you benefit from the investment in reliability and high technical standards of our products and services.